We use a boroscope camera inspection to determine the initial condition of the pipe. This will clearly show any defects and general condition of the internal pipe structure.

The camera inspection is vital in locating defects in the pipework.

The areas which are to be repaired are marked ready for the next process.

Once inspected, the pipe is drained and pressure tested to determine the leakage rate.

All test results are recorded and used to compare and clarify the effectiveness of any repair we carry out on your behalf.

Depending on the diameter of the pipe, the pipe is cleaned using mechanical tools or mineral aggregate introduced via a channelled airflow.

This clears the pipe of any obstructions and prepares the interior surface of the pipe to receive the protective coating

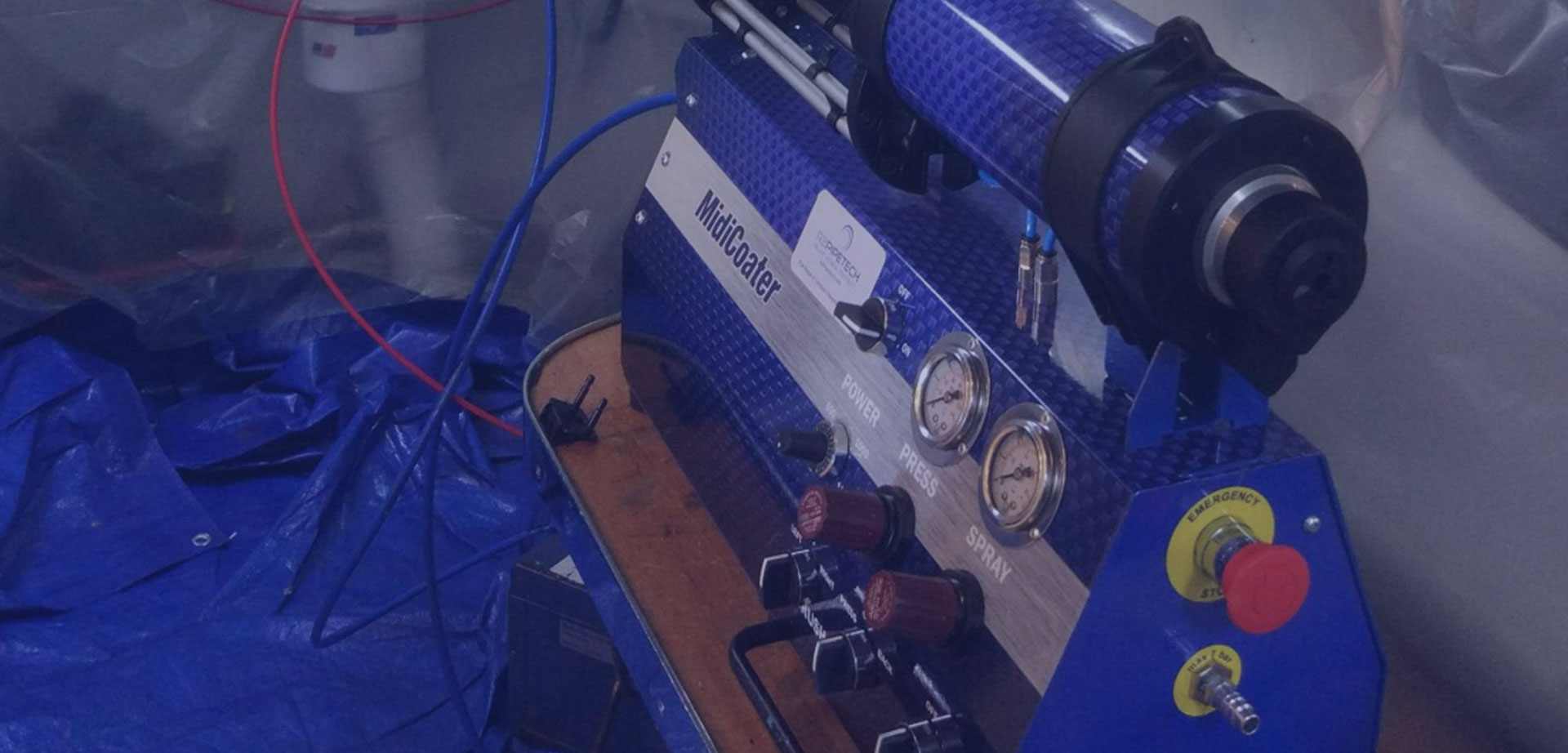

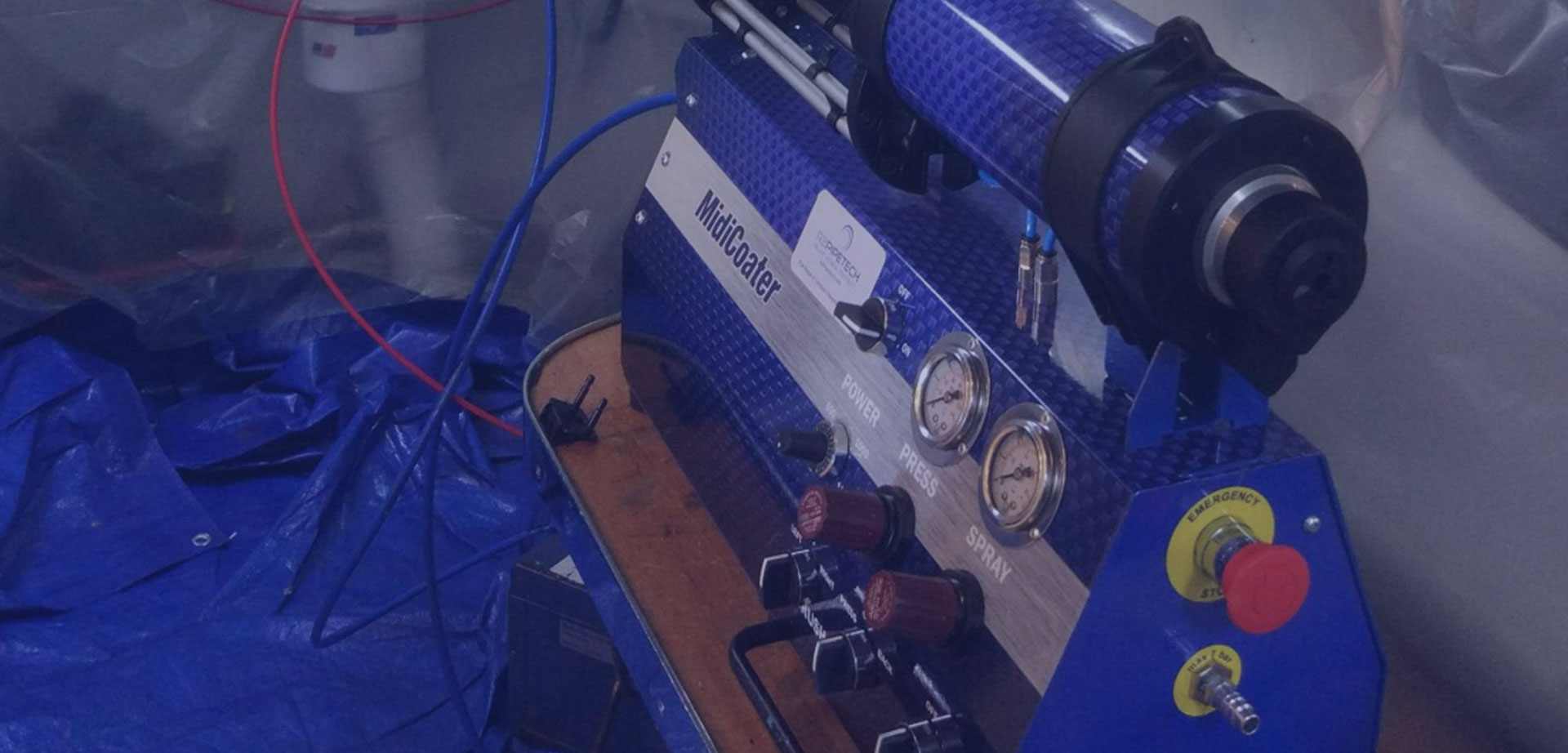

We then apply our barrier coating to internally line the inside of pipe, this seals any leaks, loose threads and protects the pipe from further corrosion for decades to come.

After the coating, we allow the material to cure for two hours, this allows a hard film barrier to form protecting the pipe interior.

The pipe is boroscope camera inspected again and then pressure tested to ensure complete coverage.

The fully repaired pipe can then be reinstated ready for years of uninterrupted service.