Customer:

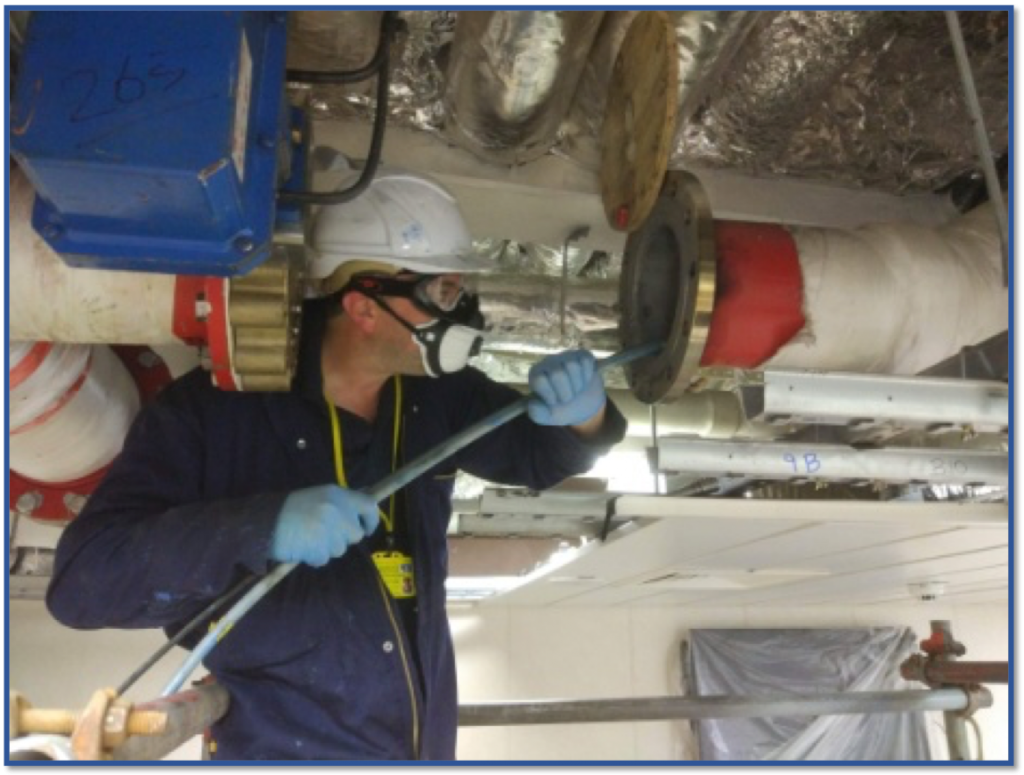

Military Vessel

System:

Fire suppression system, 150mm (6”) – 200mm (8”) diameter pipes, suffering from pitting and corrosion attributed to Electrolysis

Problem:

The fire suppression system is essential on any operational vessel, the system is constantly charged with sea water ready for emergencies at the turn of a valve.

Corrosion has led to through-wall corrosion, wall thickness loss and leaks in many of the various pipes throughout the vessel.

One leak caused severe damage to on-board electronics and computer systems.